Sectors We Support

From design to construction, we succeed when you do.

-

Generation

The energy generation industry is at the threshold of its metamorphosis from the centralized heavy industry of the past, like the steel and mining industries of the 19th and 20th centuries, toward a more sustainable and eventually cost effective decentralized future. Tri-Technic supports any and all types of power generation facilities. »

-

Delivery

The electric national, regional and local power transmission and distribution network is the facility which transports and delivers bulk electrical energy from the generators, through our system of lines and substations, ultimately to all of us who need and use the energy, to build and sustain an advanced society, safe and comfortable communities, and the most vibrant economy on earth. »

-

Utilization

Energy utilization is where the energy supply meets the needs and demands of a civilized society. Utilization focuses on the equipment, appliances and technologies that provide for civilized life. All industries, life sustaining water, our food, sanitation, data and communications and every facet of civilized life, fades and dies without energy, delivered when, where and in the right quantity needed to sustain our lives and well-being. »

-

Storage

Energy storage is the only facility that can support the continued utilization of renewable energy in our electric power generation and delivery systems. Without Storage, continued penetration of renewables into our energy systems, will cause our entire system to fail and collapse. Storage in all its forms, is the only thing that fixes the problems that renewables create; Storage is critical. »

-

Microgrids

A microgrid is a relatively small, localized system of Energy Resources and Utilization Loads that typically operates connected to and synchronous with the traditional centralized power grid (macro-grid), but is able to disconnect and maintain local operation, autonomously as system reliability and/or economic conditions dictate. Currently Microgrids are built for sustainability and to support critical missions and operations, rather than energy economics. »

Generation

The energy generation industry is at the threshold of its metamorphosis from the centralized heavy industry of the past, like the steel and mining industries of the 19th and 20th centuries, toward a more sustainable and eventually cost effective decentralized future.

The old, centralized energy production and delivery systems enjoy stability and economies of scale, built over the past 150 years. The new decentralized systems, still have a long way to go to achieve the efficiency, power quality and reliability that the old institutional system has enjoyed for more than a century. Decentralized energy will get there, it will just take time.

Huge empires were built over more than a century, on the centralized energy systems of the past; very hard to overthrow. New empires will be built on the new decentralized systems, but they are very fragile now and must go through much evolution and consolidation before they are strong. Until then Tri-Technic will continue to do our part working in and on the centralized energy grid, to assure the needs of civilized society are met through efficient, cost effective and reliable energy generation, delivery and utilization.

Power Generation

Tri-Technic has proven success and experience in navigating through complex, challenging, and schedule-intensive power plant construction, refurbishment and maintenance projects; including combustion and steam turbines; combined heat and power – CHP, co-generation plants, internal combustion engine-generators, whether diesel fueld, bunker oil or JP-5/8 fueled, or hydroelectric plants; including all balance of plant and fuel storage facilities; for utilities, industry, and government agencies.

We are adept at controlling the convergence of multiple construction disciplines. We maintain tight project controls and closely manage subcontractors, field personnel and staff allowing us to meet our clients’ highest expectations for safety, quality, schedule, budget and productivity, as required for every project.

All projects are completed on time and within budget. Tri-Technic has earned a valued position in the industry, because we control the details, and adhere to the fundamentals; this is the formula for success on every project, no matter how big or small; the fundamentals always work.

Renewables

Green energy is rapidly evolving and will someday supplant conventional coal and natural gas as the dominant energy resource nationally and globally, as new technologies are developed and implemented. Government mandates to increase green energy indicate a clear commitment to reducing our national carbon footprint, as well as bringing clean, renewable energy sources to people around the globe.

With the exception of hydroelectric, hydrogen fuel cells, thermal solar, tidal and wave power, and geothermal generation, which are very complex systems, the predominant renewable energy sources in the market are wind and photo voltaic solar (PV). These are certainly products of advanced technology, inside their patented assemblies, but both have become simple basic commodities from a construction and installation perspective, which is a good thing for the energy industry. Costs must come down, in order for renewables to be viable and meaningful in the national and global energy mix, and commoditizing them is the right evolution.

Just about anyone can put the components together and make them work, but doing so on a utility / grid scale, on time, on budget, with high levels of safety and quality is quite a different matter. “Utility scale” takes a team like Tri-Technic to effectively bring them into reality. The more complex alternative energy sources; hydroelectric, hydrogen fuel cells, biomass, thermal solar, tidal power, wave energy, waste to energy, geothermal and the like, are all less complex than combustion turbine or steam turbine plants and thus are well within our considerable expertise. Based on Tri-Technic’s related expertise, we are well positioned, ready and able to perform very well in the construction of any alternative energy project. Whether bid-build or design-build is needed, Tri-Technic is an exceptional choice.

Delivery

Efficiency, reliability, and access to clean, renewable energy are the directives that guide construction in today’s Electrical Power Industry. These same directives drive Tri-Technic’s work and performance for our Power Industry clients across our geographic market. Tri-Technic’s familiarity with the Power Industry encompasses a diverse array of the industry’s most challenging and complex construction.

We employ strong management practices, set project goals, and pay close attention to detail. Tri-Technic constantly measures progress and productivity to ensure that every project meets critical schedule deadlines while upholding budget controls and exemplary safety standards and quality performance.

Tri-Technic has an extensive track record of performing successful projects in many Power Industry segments, including: Power Plants / Transmission Lines / Substations & Switch Yards.

Transmission & Distribution

Reliability, quality, and adequate, if not abundant energy supply availability, at reasonable cost are the directives that guide our national and global energy delivery systems. Tri-Technic is and has for many decades been deeply involved in the delivery of electrical energy, from all of its generation sources, through the complex national, regional and local energy grid systems, with all related transmission, distribution, industrial / facilities substations; from 500KV interstate transmission systems, down through 4KV local industrial / facility / campus grid delivery systems, down to the low utilization and control voltages required to bring energy from where it is produced, to exactly where it is needed, safely and efficiently, to perform the heavy work required by a civilized society; keeping the wheels of progress turning.

HDVC

Whether located hundreds of miles apart and applied for Long Haul Power Transmission connected via overland tower lines or submarine cables, or applied back-to back for grid synchronization, Tri-Technic is experienced in building and retrofitting HVDC Converter Stations.

We have completed Converter projects through 3,100MW at 500kV in the U.S. and we have demonstrated the capability to successfully complete projects into the largest MW and UHV ranges found in the world today. We are the Experts at Building & Retrofitting HVDC Converter Stations Our capabilities also assure success in building or retrofitting SVCs, the HVDC Converter’s smaller cousin. Whether the application requires conventional thyristor valve converters or the newer Insulated Gate Bipolar Transistor (IGBT) based converters, Tri-Technic is able and willing to provide these services and apply our expertise anywhere in the world

Utilization

Energy utilization focuses on technologies that can lead to new and potentially more efficient ways of using electricity in residential, commercial and industrial settings—as well as in the transportation sector.

Most industries purchase electricity from electric utilities or independent power producers. Some industrial facilities also generate electricity for use at their plants using fuels that they purchase or using residues from their industrial processes. For example, paper mills may burn purchased natural gas and black liquor produced in their mills for process heat and to generate electricity. Some manufacturers produce electricity with solar photovoltaic systems located on their properties. Some industrial facilities sell some of the electricity that they generate.

Industrial

Heavy Industrial projects are very detailed and complex, and they are normally mission critical; often facing the additional challenge of keeping facilities up and running safely and effectively, while improvements or project construction is underway. Tri-Technic’s experience, attention to detail, exceptional project management, and experienced crews meet and overcome those challenges and the unforeseen obstacles that often negatively impact the success and safety of these projects. We assure success in all our projects, by applying the fundamentals of extensive and detailed planning; organizing our resources around our plans, and flawlessly executing. Execution comes only after every task is thoroughly planned and organized, and our plans well communicated and coordinated with the designated stake-holders.

Our Heavy Industrial work routinely involves retrofit and new construction of a broad spectrum of manufacturing and processing plants; refineries; gold and other minerals, mining and processing; complex water and wastewater treatment, and pumping facilities; scientific / research / testing facilities; super-computing facilities; plasma-arc furnaces to 60MW; all sizes and types of motors and controls from small specialty motors through synchronous motors to 5,000hp, 120vdc, 480vac to 13,800vac, and everything around and in between. Our projects routinely involve highly constrained schedules; intense operational and security constraints and extremely high levels of safety and environmental scrutiny; this is the world we operate in on a daily basis.

Storage

Energy storage is rapidly becoming a mainstream energy resource which facilitates and accelerates the adoption of renewable energy technology and promotes a more sustainable, reliable, affordable, and secure electric power system.

Energy storage is integrated into our energy grid through a number of technologies and designs; each contributing to our sustainability in their own unique ways, all of which, in combination, are critically important to renewable grid infrastructure.

Tri-Technic has extensive experience in the field of energy storage in most of its forms, and is very well positioned in the energy industries to develop, design and construct the most complex of these projects and systems.

Battery

Structurally battery storage power plants and uninterruptible power supplies (UPS) are comparable, although the former are larger. The batteries are housed for security in their own warehouses or in containers. As with a UPS, a problem is that electrochemical energy is stored or emitted in the form of direct current (DC), while electric power networks are usually operated with alternating current (AC). For this reason, additional inverters are needed to connect the battery storage power plants to the high voltage network. This kind of power electronics includes GTO thyristors, commonly used in high-voltage direct current (HVDC) transmission.

Various accumulator systems may be used depending on the power-to energy ratio, the expected lifetime and, of course, the costs. In the 1980s, lead-acid batteries were used for the first battery-storage power plants. During the next few decades, nickel-cadmium and sodium-sulfur batteries were increasingly used. Since 2010, more and more utility-scale battery storage plants rely on lithium-ion batteries thanks to the fast decrease in the cost of this technology, driven by the electric automotive industry. Lithium-ion batteries are mainly used, some redox flow system has emerged and lead-acid batteries are still used in small budget applications.

Generally grid scale storage breaks down into 5 primary classifications of energy storage: Chemical; Thermal; Electrical; Mechanical; Fuels.

It is important to note that no one or no process is creating energy. In storage, as in all generation / production, we are only gathering up energy dense materials from where they are not being used and directing / re-deploying them to where and when they are needed. The thing is with all these energy storage media, what we are doing is capturing excess electrical energy. Which has to be generated by other means, with all its initial capital costs and normal inherent loss inefficiencies. Capturing and storing that energy into chemical, thermal, electrical, mechanical media, with their initial capital costs, and their inherent round-trip loss inefficiencies. So we can easily see that Stored Energy is the Most Expensive Energy. Having thus said, we have no choice but to deploy (and pay for) massive amounts of energy storage, in order to support the new green economy and government mandates, while working to preserve the viability of our energy grid against collapse. Energy storage is becoming and always will be an integral part of a green, renewable, sustainable energy grid.

Tri-Technic has extensive experience in the field of energy storage in most of its forms, and is very well positioned in the energy industries to develop, design and construct the most complex of these projects and systems. Tri-Technic performs exceptionally on energy storage projects by close adherence to the tried and proven fundamentals, implemented through utilization of current methods and technologies, that work.

Chemical Storage

Chemical Storage includes batteries, which include dozens of diverse chemistries in the market, Li-Ion, lead-acid, redox flow, metal-air, and others; hydrogen; ammonia; bio-energy and the like. Chemical Storage is currently effective from 4 and up to 8 hours in limited application but becomes cost prohibitive beyond these limits. The exception to this rule is for hydrogen, which can potentially store energy for years.

Thermal Storage

Thermal Storage includes; steam, hot water, molten salt, rock storage and similar heat-sink media; ice, chilled water, refrigerant and other thermal fluid transfers. Stirling engines; to geothermal and all related technologies. Thermal Storage is effective from several hours to several days. Beyond that point it loses its effectiveness.

Fuels Storage

Conventional generation, as we have all grown up with; Coal, Natural Gas, Fuel Oil, Nuclear produces fuels. Extracting, processing / refining, transporting, storing, and using it to serve our needs when and where we need energy. This “Fuels Storage”, is simply a re-deploying of energy that is latent in the earth.

This form of energy storage is the most effective and robust. It can and routinely does store energy for weeks, months, years. It is important to note, that it takes a considerable amount of energy to gather and re-deploy all forms of this type of energy.

Mechanical Storage

Mechanical Storage is probably the most diverse and versatile of all energy storage categories. This group would include gravity storage. Gravity power has many forms including pumped hydro and similar technologies such as inertia storage, including flywheels and synchronous condensers. Similar equipment including compressed air, such as for powering air-motors or ram-jet enhancements to combustion turbines.

This short list encompasses literally hundreds of mechanical designs that can scale from small distribution connected storage equipment, up to very large transmission source equipment. These technologies can provide energy storage from a few minutes to many hours to potentially months.

Electrical Storage

Electrical Storage, although we seek to store this form of energy, it is the most limited of the storage media, generally limited to super-capacitors, capacitors and reactors. These solutions can only store energy from a few cycles to a very few minutes but for grid support, they certainly have their value.

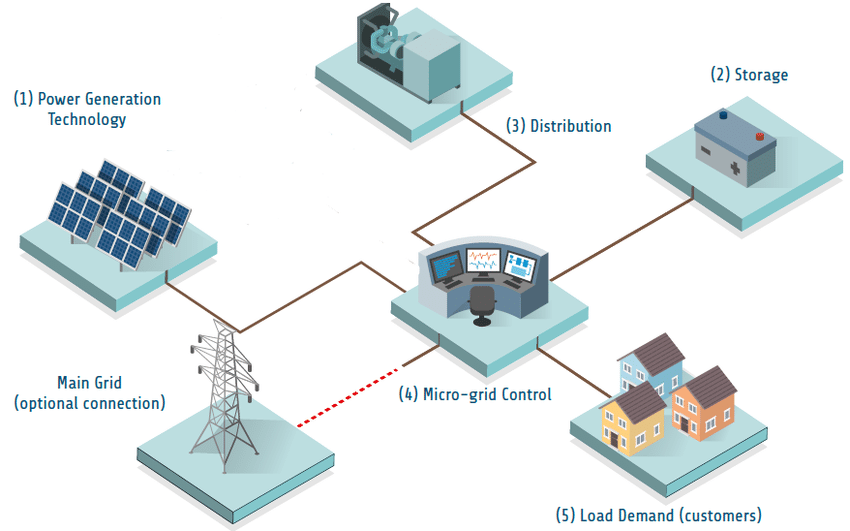

Microgrids

A Microgrid is a localized aggregation of energy resources and utilization loads that normally operate connected to and synchronous with the traditional wide area (macro) grid, but can also disconnect to “island mode” and function autonomously as physical, environmental or economic conditions dictate.

In this way, a microgrid can effectively integrate various sources of distributed generation (DG), especially Renewable Energy Sources (RES) – renewable electricity, and can supply emergency power, changing between island and connected modes.

Tri-Technic is well positioned and experienced to advise, consult, develop, design and construct microgrids on most any scale; grid-connected, island / off-grid or mission critical; from small communities, industrial parks, critical facilities and campuses; to large industries, critical government complexes and military bases. Tri-Technic is at home in all these facilities and environments and we have the teams that can meet these challenges and get your job done.

Microgrid Overview

Microgrids employ, equipment and resources that most of us are familiar with, but integrating all these common resources, plant and equipment into a reliable, efficient and sustainable system is not so easy. All of our energy systems, throughout all of history, have been designed and constructed to facilitate the safe and efficient delivery of our energy in one direction; from large, centralized sources, through the well-established and robust distribution systems, to our various loads, to perform the work and provide lifestyle that we all demand.

Our loads and the work we require of our energy have really not changed a lot over the years; incremental efficiency improvements and more sophisticated means of controlling these loads has evolved, but very little relative to the actual utilization equipment itself.

However, Distributed Energy Resources (DERs) is a wild-card that has recently entered the game. 10 years ago, very few people or companies would have ever contemplated owning and operating their own energy systems, but now with DERs and energy storage assets becoming more readily available and economical, many are finding that this prospect may now be within reach. The question is not whether we can, but whether we should attempt to own and operate our own energy systems? With continually rising commercial energy costs and the continual degradation of service and accountability from our traditional energy providers, those questions are being asked a lot more these days.

There are generally 4 basic building blocks for all microgrids, which must be addressed and mastered in order to implement an effective and sustainable microgrid; the DERs; the energy delivery systems; managing and prioritizing the utilization loads; and an effective microgrid controller to manage and control all the other systems and equipment. We are all familiar with on-site, stand-by generators, and PV and wind DERs, have pretty well matured and are pretty common commodities these days; most of our energy delivery / distribution systems are in-place and reasonably adequate; however, energy storage and microgrid controllers are anything but mature or reliable at this point. Many attempts at developing, designing, constructing and operating microgrids have failed miserably, because the fundamentals have been ignored. The tendency is to start with the equipment, but this is starting at the wrong end and will assuredly lead to failure.

Remote Off-grid Microgrids

These microgrids never connect to the Macrogrid and instead operate in an island mode at all times because of economic issues or geographical position. Typically, an “offgrid” microgrid is built in areas that are far distant from any transmission and distribution infrastructure and, therefore, have no connection to the utility grid. Studies have demonstrated that operating a remote area or islands’ off grid microgrids, that are dominated by renewable sources, will reduce the levelized cost of electricity production over the life of such microgrid projects.

Large remote areas may be supplied by several independent microgrids, each with a different owner (operator). Although such microgrids are traditionally designed to be energy self-sufficient, intermittent renewable sources and their unexpected and sharp variations can cause unexpected power shortfall or excessive generation in those microgrids. This will immediately cause unacceptable voltage or frequency deviation in the microgrids. To remedy such situations, it is possible to interconnect such microgrids provisionally to a suitable neighboring microgrid to exchange power and improve the voltage and frequency deviations. This can be achieved through a power electronics- based switch after a proper synchronization or a back to back connection of two power electronic converters[18] and after confirming the stability of the new system. The determination of a need to interconnect neighboring microgrids and finding the suitable microgrid to couple with can be achieved through optimization or decision making approaches.

Community Microgrids

Community Microgrids can serve up to a few thousands of customers and support the penetration of local energy (electricity, heating, and cooling). In a community microgrid, some houses may have some renewable sources that can supply their demand as well as that of their neighbors within the same community. The community microgrid may also have a centralized or several distributed energy storages. Such microgrids can be in the form of an ac and dc microgrid coupled together through a bi-directional power electronic converter.

Campus Environment/Institutional Microgrids

The focus of campus microgrids is aggregating existing on-site generation with multiple loads located in tight geography in which owner easily manage them.

Commercial & Industrial (C&I) Microgrids

These types of microgrids are maturing quickly in North America and Asia Pacific; however, the lack of well –known standards for these types of microgrids limits them globally. Main reasons for the installation of an industrial microgrid are power supply security and its reliability. There are many manufacturing processes in which an interruption of the power supply may cause high revenue losses and long start-up time. Industrial microgrids can be designed to supply circular economy (near-)zero-emission industrial processes, and can integrate combined heat and power (CHP) generation, being fed by both renewable sources and waste processing; energy storage can be additionally used to optimize the operations of these sub-systems.

Military Base Microgrids

These microgrids are being actively deployed with focus on both physical and cyber security for military facilities in order to assure reliable power without relying on the Macrogrid.